Both sandblasting and dry ice blasting can be ideal choices for surface cleaning, depending on the specific requirements of the task at hand. However, these two methods have many similarities and differences.

Sandblasting is a renovation cleaning process by which sand, or an abrasive substance like sand, and water are directed by a high airflow onto a surface, typically to remove paint or grime or to intentionally increase the roughness of a surface. It has been used as standard practice in construction and renovation since its invention in the late 1800s.

Dry Ice Blasting, such as that offered by Raw Restoration Blasting in Burlington, Wisconsin, is a surface treatment method that is used for the same types of projects as sandblasting, only using more advanced, more environmentally-friendly techniques and equipment.

It is perfect for Wisconsin’s harsh winters because it does not introduce moisture into the process, as sandblasting does. Sandblasting moisture can freeze and become problematic. The dry ice blasting technique does not conduct electricity, so it is safe for use on and around electrical equipment where the use of water is unsafe and impractical.

Dry ice blasting causes a thermal shock to the surface being cleaned that is due to the change in temperature caused by the dry ice pellets. When the dry ice pellets are introduced to the surface, a much lower temperature is used than that of sandblasting. The temperature of dry ice is usually around 78.5 degrees Centigrade or -109 degrees Fahrenheit. It causes a fast cooling of the surface contaminants, which leads to the aforementioned thermal shock, which does not expand the surface as the hotter sandblasting temperatures do.

Why Is Dry Ice Blasting Better Than Sandblasting?

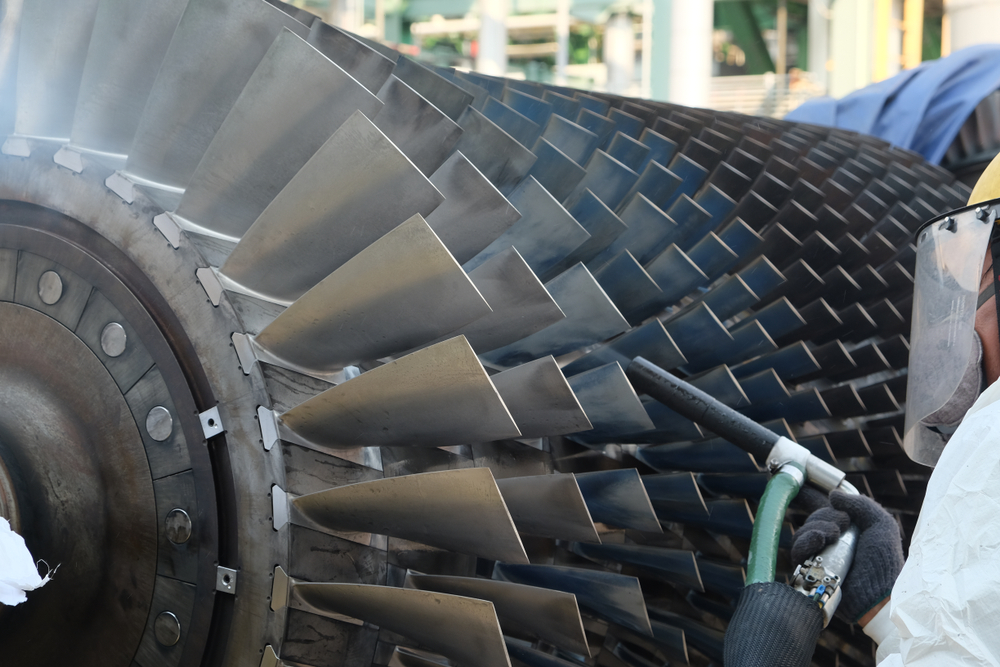

Dry ice blasting is often the preferred blasting method over sandblasting because it does not create the same abrasive damage to surfaces that sandblasting is notorious for creating. It can be used on delicate surfaces that would otherwise be destroyed by sandblasting and do not erode or damage any materials beneath the surface being blasted.

While sandblasting creates a huge mess that deposits secondary waste at the site, dry ice turns directly from solid material to gas, which leaves only the material that is removed from the surface being blasted without residual material to have to clean after the job is finished.

Dry Ice Blasting Is Better for the Environment

Workers who do sandblasting are required to wear specially-designed face masks because the process results in harmful dust. Additionally, the used sand has to be disposed of, which is not as environmentally friendly as the dry ice blasting process. While sandblasting can be biodegradable, it can also cause substantial damage to the environment. Dry ice blasting does not fall into this category and is much more sustainable.

Because dry ice is basically water, it is non-hazardous and non-toxic. This makes the process much better for the environment than sandblasting. Dry ice blasting, also known as C02 cleaning, even goes so far as to remove air emissions that can be harmful to the lungs, and it does not add to the volume of waste created by the cleaning process. The dry ice pellets used in the process are created from recycled carbon dioxide, which does not contribute any new C02 into the atmosphere.

Less Wear and Tear on Equipment

Due to the aggressive nature of sandblasting, the equipment used to do it frequently needs to be repaired or replaced. This makes the technique much more expensive, in general, than that used with dry ice blasting because downtime must be figured into the cost. Sandblasting equipment not only requires disassembly. It also requires relocation to a different, more controlled environment.

Dry ice blasting places much less wear on the equipment because the dry ice pellets are softer than the sand used in sandblasting. Dry ice equipment holds up longer without needing repair or replacement and ends up costing much less to use. When it does require repair, dry ice equipment does not require disassembling.

Dry Ice Blasting Can Be Used in a Wider Variety of Environments

Food processing plants are but one of the environments where dry ice blasting can be used, but sandblasting is unsuitable. This is because dry ice blasting does not leave the type of residue that sandblasting does. The latter might contaminate food products with the harmful dust that it creates.

Since sandblasting frequently causes abrasive surface damage, contractors often hire dry ice-blasting experts to use this method on more delicate surfaces, such as carved plaster impressions in historical buildings and carved statuary.

Additionally, dry ice blasting can be used on rusted metals without further damaging the metal beneath. This is not true with sandblasting because it is too abrasive. When used on rusty metal, sandblasting can penetrate the surface of the metal and destroy its integrity. Dry ice blasting is gentler than sandblasting. Therefore, it is used more often in situations where historical renovations require a gentler surface cleaner.

Dry Ice Blasting Contributes to Less Noise Pollution

By definition, construction and renovation sites can be very noisy. They are where things are built, rebuilt, torn apart and reassembled.

Dry ice blasting is considerably quieter than sandblasting, which can be quite noisy. Dry ice blasting is ideal for areas such as hospitals, which are particularly noise-sensitive.

Call for a Consultation

If you are interested in exploring the benefits of dry ice blasting for your cleaning needs, we encourage you to reach out to our professionals at Raw Restoration Blasting. Our family and veteran-owned business, located in Burlington, Wisconsin, is committed to continually providing restoration services that meet our clients’ resurfacing needs without the use of the abrasives, chemicals, or water used in sandblasting. Our company is a fully licensed and insured entity with a team of experienced professionals to assist with all of your resurfacing and restoration needs. Get started by contacting our team today at 262-417-6836 to get a free quote from one of our resurfacing experts, who will be happy to answer any questions that you may have.