When it comes to maintaining tire manufacturing equipment, cleanliness isn’t just about appearances. It directly affects performance, safety, and downtime. That’s why more and more manufacturers are choosing dry ice blasting as the go-to solution for equipment cleaning. This method is fast, effective, environmentally friendly, and ideal for high-precision manufacturing environments like tire production.

At Raw Restoration Blasting, we specialize in bringing advanced cleaning technology to industries that can’t afford delays or damage. As a family- and veteran-owned business based in Burlington, WI, we’re proud to offer dry ice blasting to tire manufacturers looking for a better, cleaner way to maintain their operations.

What Is Dry Ice Blasting?

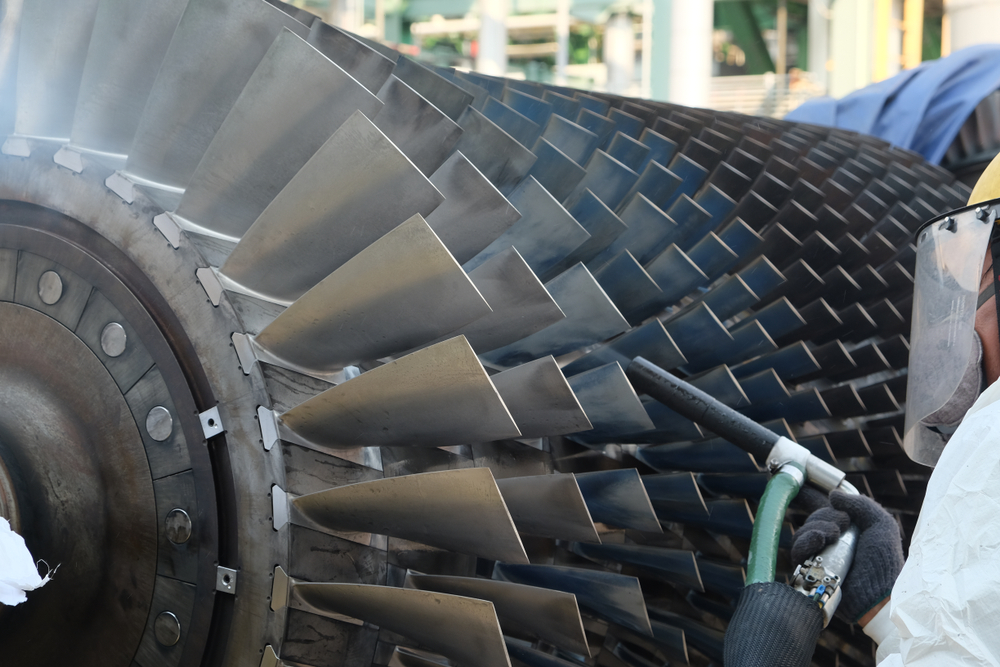

Dry ice blasting is a cleaning method that uses solid carbon dioxide (CO₂) pellets, also known as dry ice, to remove contaminants from surfaces. The pellets are shot out of a nozzle at high speed. When they hit a dirty surface, they cause the dirt, grease, rubber, or other buildup to crack and break away.

The key to its power is the rapid temperature change. The dry ice instantly drops the surface temperature, causing materials to contract and separate. Then it evaporates into a gas, leaving no residue behind. That makes dry ice blasting a non-abrasive, chemical-free cleaning method that is perfect for sensitive or complex machinery.

Why It’s Perfect for Tire Manufacturing

Tire production involves a lot of rubber, heat, and heavy machinery. Over time, that means buildup, like sticky residues, mold release agents, grease, and carbon deposits that can slow down or damage equipment. Traditional cleaning methods like scraping, scrubbing, or pressure washing can take hours, risk damaging the machinery, or require full shutdowns.

With dry ice blasting, you don’t need to disassemble the equipment. Our team can clean machinery in place, even while it’s still warm, which saves time and reduces costly downtime. It’s gentle enough to use on sensitive equipment, yet powerful enough to remove the toughest buildup.

Environmentally Friendly and Safe

One of the biggest advantages of dry ice blasting is that it’s safe for your team and the environment. We don’t use water, chemicals, or abrasive materials. This means there’s no risk of corrosion or toxic runoff.

For industries focused on sustainability and compliance with strict regulations, dry ice blasting helps you stay in line with safety and environmental standards. It also keeps your facility cleaner, which is important in reducing the risk of workplace accidents and machine failure.

Reduced Downtime, Increased Efficiency

Tire manufacturing equipment doesn’t have time for extended breaks. Every hour of downtime can mean lost productivity and missed deadlines. Unlike other methods, dry ice blasting allows us to clean without long prep or drying times.

Since the dry ice pellets evaporate on contact, there’s no need to wait for parts to dry or be reassembled. Your machines can be back up and running quickly, often within the same day. This is a huge benefit for tire plants that run 24/7 operations and can’t afford long shutdowns.

Preserves Equipment and Saves Money

Using dry ice blasting regularly helps extend the life of your tire manufacturing equipment. Because the process is non-abrasive, it won’t scratch or wear down parts like traditional methods can. This means fewer repairs, fewer part replacements, and better overall performance from your equipment.

Keeping machinery clean also helps you spot problems early, before they lead to major failures. Our clients often tell us how much smoother their equipment runs after blasting. It can even help reduce heat build-up and improve overall efficiency.

Customized Solutions for Your Facility

Every tire manufacturing plant is different, with its own layout, equipment, and cleaning challenges. That’s why we tailor every dry ice blasting job to your specific needs. Whether you need a full production line cleaned or just targeted maintenance on key machines, our team will develop a plan that works for your schedule and budget.

We also work hard to minimize disruption to your operations. Our experienced technicians understand the demands of the manufacturing world, and we pride ourselves on offering prompt, professional service that keeps your plant running smoothly.

Why Choose Raw Restoration Blasting?

At Raw Restoration Blasting, we bring the best of modern cleaning technology to local businesses at prices that compete with pressure washing or traditional media blasting. As a family- and veteran-owned company, we care deeply about doing the job right and treating our customers with honesty and respect.

We’re not just a contractor; our team is truly a partner in your success. That means showing up on time, delivering top-quality work, and helping you reduce downtime, lower costs, and protect your equipment.

When you’re ready to try dry ice blasting for your tire manufacturing facility, we’re ready to help.

Contact Us Today

Give your tire manufacturing equipment the deep clean it deserves. Choose dry ice blasting from Raw Restoration Blasting and see the difference in safety, speed, and performance.

Call Raw Restoration Blasting at (262) 417-6836 to request a free quote. Serving Burlington, WI, and surrounding areas, we are your trusted source for advanced surface preparation and eco-friendly cleaning solutions.