Dry ice blasting is FDA, USDA, and EPA approved and deemed the safest cleaning method with no harmful waste substances. So if you’re looking for an environmentally friendly and time-efficient cleaning method, consider dry ice blasting.

The question is, what is dry blasting, and how does it work? If you’re new to dry ice cleaning, this guide will tell you everything you need to know. You can swap from potentially toxic or lower-quality cleaning to dry ice blasting today.

What Is Dry Ice Blasting?

Dry ice blasting is an environmentally-friendly technique. The machine will flow liquid CO2 into a container and is then rapidly decompressed. This process forms dry ice that forms into small pellets.

It is these 3mm pellets that will come out of the dry ice blasting machine at high speeds of over 150 m/s. The CO2 pellets are -79°C and can be used to clean or maintain surfaces safely.

Once the pellets come into contact with the dirt, a quick chemical reaction occurs to remove the substance.

The Science Behind Dry Ice Blasting

There are three stages to the dry ice blasting process, but they occur within seconds. So you can finish work, traditionally done by hand, much quicker. There is also no secondary waste from the process.

1. Kinetic Effect

The dry ice blasting machine will blast dry ice pellets at the cleaning surface. As they make contact with the substance, it causes a crack. This step is unique because it won’t cause any damage to paintwork or material underneath the dirt.

2. Thermal Effect

The temperature of the hit area will rapidly decrease as the dry ice penetrates the substance. Consequently, the dirt particles will contract, lose grip, and fall to the ground.

A natural temperature difference between the dirt and the cleaning surface ensures a clean separation.

3. Sublimination

At the same time, the CO2 pellets transform into non-toxic CO2 gas and expel outwards. This expansion causes a mini-explosion that shatters dirt and foreign substances attached to the surface.

Finally, a clean and dry surface will remain. Afterward, you will need to collect and dispose of the foreign substances and dirt on the floor.

Pressure Washers and Sandblasting Versus Dry Ice Blasting

Unlike sandblasting, blasting with dry ice is a non-mess process. Sandblasting can leave a grainy residue in the crevices of intricate surfaces, such as statues. The sand dust caused by sandblasting can lead to serious health problems, so you must wear protective gear.

However, because dry ice transforms into gas, there is no lasting residue or toxic waste.

Pressure washers are the slower of the three techniques and require more hands-on cleaning. For example, pressure washing a car’s suspension will take twice as long as dry ice blasting. As a tip, you’ll want a selection of nozzle sizes to manage the pellet pressure.

Dry ice cleaning requires no additional scrubbing, so it is an ideal option for people with limited mobility or energy. We recommend starting with a google search for “dry ice blasting near me” to see available options.

Plastic and Rubber Injection Molding

Use a small dry ice nozzle for the ultimate precision when cleaning injection molds. Considering that the process is hands-off, you can start cleaning even while the injection molds are still hot. In addition, dry ice blasting is suitable for use on medical molds.

Residential Deck Resurfacing

Decking is prone to damage caused by moving furniture, children playing, and the weather. Cleaning with dry ice blasting is a one-step non-toxic, and fast process.

So, even if your children are around, you don’t need to worry about them inhaling toxic fumes. You’ll also be left with a 100% dry surface so you can immediately resurface your decking.

Fire Restoration

After fire damage, dry ice blasting is the ideal system to clear soot and char. Many people choose this method because it is dustless. In addition, fire restoration projects have a short timeframe for restoration.

Dry-ice blasting is one of the quickest cleaning processes, so you can finish the initial cleaning within a few days. It will give you enough time to complete the other tasks.

Construction Equipment Maintenance

Tar, oil, and grease can slow down and damage your construction or industrial equipment. Dry ice blasting does not involve water and will leave your gear clean and dry. As such, you’ll be able to return to work quickly after cleaning.

Nuclear Decontamination

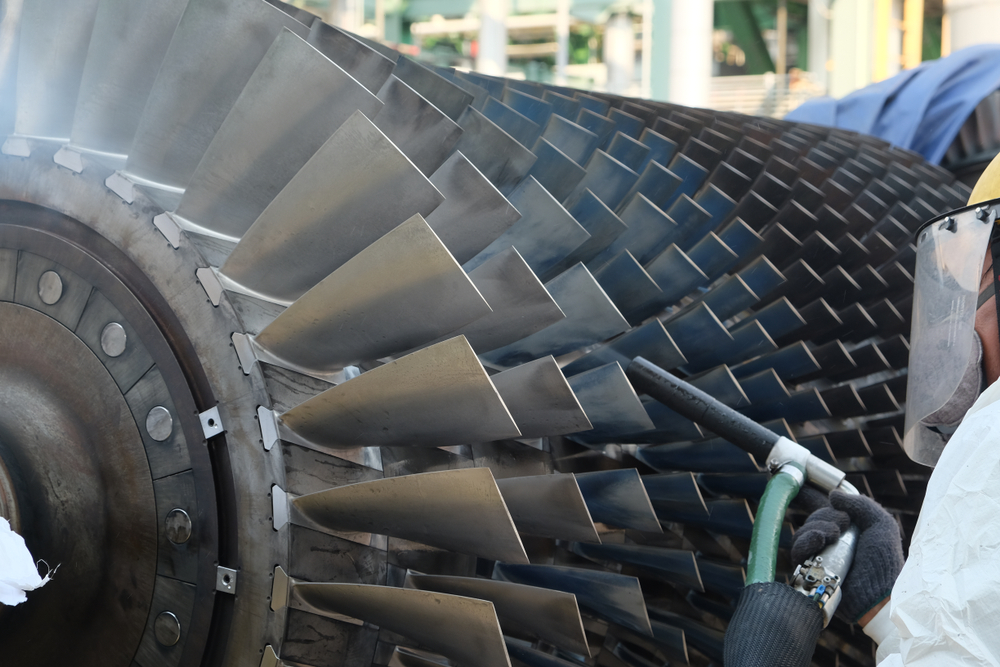

Professionals in the nuclear industry use a dry ice blasting machine to clean and decontaminate zones. It will decrease hazardous waste disposals and can decontaminate the hairpin exchanger, condensers, steam turbines, motor tubes, and more.

Historic Landmark Preservation

Unfortunately, people deface historic landmarks with graffiti. Previous cleaning methods of historic buildings caused lasting damage. Grafitti is an easy removal task for a dry ice blasting machine.

Hold the nozzle in your hand and move it from side to side. Most graffiti will need only one blast to remove the design. So, cleaning historic landmarks is now a labor and cost-efficient process.

Marinas

It can take people four weeks to clean a boat for storage. One of the main problems is removing barnacles from the hull. But with an ice blaster, marine cleaning can be done in a day.

Also, when removing barnacles by hand, you can damage the underneath paintwork. As mentioned earlier, this isn’t a risk with dry ice blasting. You can also clean the internal parts, sterndrive, and deck.

Dry Ice Blasting for the Ultimate Clean

Dry ice blasting is the perfect cleaning machine, whether you need it for commercial, construction, or residential purposes. You’ll finish quicker and have a much deeper and sterilized clean.

It’s a worry-free solution for our industries. So, contact us today to discuss how dry ice blasting could be your cleaning solution.