The surface preparation abrasives market is projected to reach $11.2 billion by 2027, growing 4.12% in total. In the past, sandblasting was the obvious choice for surface preparation. It was effective and had stood the test of time.

The problem is that sandblasting isn’t all smiles and rainbows. There are some serious downsides to sandblasting. The industry is increasingly looking to dry ice blasting as an alternative.

We’re going to break down how each one works and look at the pros and cons of each. By the end, you’ll be clear about the right choice for your business.

What Is Sandblasting?

Sandblasting is a surface preparation technique that uses an abrasive – sand – to remove top surfaces from materials. The process uses a sand blasting machine that sprays sand particles at high pressure. On impact, they dislodge the top surface and leave a smooth surface beneath.

The principle is similar to using sandpaper in woodworking. It’ll remove top layers like paint and lacquer. But sandblasting, like sandpaper, also affects the material beneath.

What Is Dry Ice Blasting?

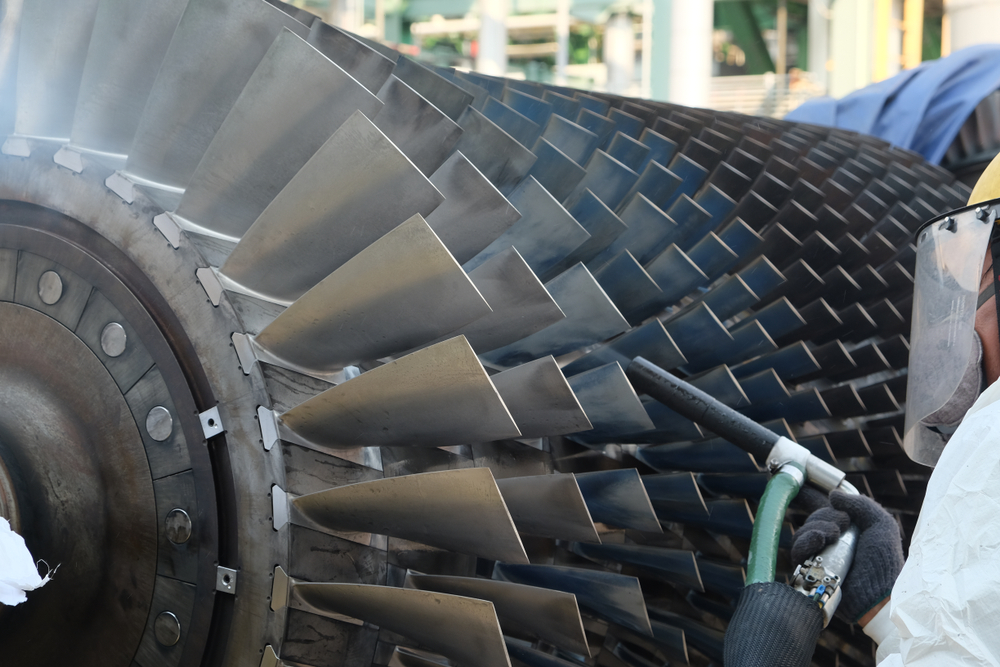

Dry ice blasting uses dry ice pellets that are projected at high speed against the surface being prepared. But that’s where the similarity with sandblasting ends.

The most important distinction between sandblasting vs dry ice blasting to mention is the abrasion factor. Sandblasting using abrasion – the physical act of the silica particles hitting the surface at high speed is what breaks it down and removes it. Dry ice blasting doesn’t use abrasion.

Instead, it uses three methods to remove the contaminant or top surface:

- Kinetic energy – the initial, high-speed impact

- Sublimation

- An extreme change in temperature – CO2 freezes at -109°F

The kinetic energy released on impact fractures the top layer.

Sublimation happens when a solid becomes a gas without going through the liquid stage. This is what happens when the dry ice hits the surface. It combines with the air, leaving absolutely no residue.

This also causes something very cool to happen. The freezing solid CO2 changes to a gas on impact. This is like a mini-explosion that rips the dirt off the surface.

The final method it uses – thermal effect – is due to the extreme difference in temperature between the surface and the dry ice. The shock of being momentarily reduced in temperature weakens the bond between the surface and the surface beneath.

Pros and Cons of Sandblasting

The benefits of sandblasting are that it’s effective and well established. It also has a wide range of applications. It creates a rough final surface, which is either a pro or a con, depending on what you’re planning to do next.

It can remove:

- Limescale

- Paint

- Rust

- Dirt buildup (such as on the external walls of buildings)

- Graffiti

Sandblasting requires a skilled operator who can carry it out with great care. It’s not effective on greasy surfaces, as the grease will cause the sand to clump and not remove the surface effectively. Always treat the surface with a degreaser first.

The cons of sandblasting for machines are that they cause damage to the surfaces they clean. This could reduce the lifespan of the machinery and parts that you’re cleaning, which kind of defeats the object of it.

Sandblasting also leaves you with a huge mess to clean up. Depending on what you’ve been sandblasting, it could be contaminated with some pretty unpleasant stuff as well.

Pros and Cons of Dry Ice Blasting

One of the major benefits of dry ice blasting is that it doesn’t use an abrasive. That means it doesn’t cause damage to the substrate. This can extend the life of machinery as the outer surface is not damaged and eroded by cleaning.

Even though dry ice blasting has a triple effect, it’s momentary and doesn’t do lasting damage. It can help your auto parts and machinery keep running for as long as possible.

Another huge benefit is that there is no residue to clean up. Because it sublimates, it leaves nothing behind. There’s no water and certainly no piles of sand to dispose of.

It’s also non-toxic and simply returns to the atmosphere.

The other great thing is that the cooling effect is very short-lived. So there’s no need to worry about your surfaces being damaged by being chilled.

When used by a skilled professional, dry ice blasting can even be used to clean equipment as is. There’s no need to break it down. It can even be used on hot equipment that is online while it is being cleaned.

The bottom line – no downtime for your business!

It’s pretty hard to find a con about dry ice blasting. Of course, the gunk and junk that was cleaned off of your machines are left behind after. But that happens with sandblasting as well, you just have it mixed in with lots of heavy sand that you need to dispose of responsibly.

You may occasionally find that there are some surfaces that dry ice blasting is not effective at cleaning. But a quick look at what it can do will show you that they’re few and far between.

Which One’s Best: Sand or Dry Ice Blasting?

Whether you choose dry ice or sandblasting, they will effectively remove surface contaminants.

However, dry ice blasting is going to extend the life of your equipment. It removes surfaces in a controlled, environmentally friendly way that involves much less cleanup. Plus, it can even work on hot machinery that’s on line.

For most businesses and homeowners, there really is one obvious winner – dry ice blasting.

How to Find the Best Dry Ice Blasting Near Me

If you’re looking for outstanding surface preparation in Racine, WI, Raw Restoration Blasting is your perfect choice.

We only use dry ice blasting to achieve excellent results for our commercial and residential clients. Whether you’re looking to clean your factory machinery or spruce up your back deck, we’re ready and waiting to help.

Call us at 262-417-6836 or get a quote online today!