Did you know that dry ice forms at a temperature colder than -100°F? You may remember this material from science class, however, it is also used in cleaning many objects and materials from home furniture to aircraft.

Are you interested in dry ice blasting as a means for Wood stripping furniture and other materials? Many people assume that getting a dry ice blasting machine is cost-prohibitive and they’ll need to find another way to strip wood.

However, it’s very possible for you to use a dry ice blaster in an economical way and simplify the stripping process.

In this article, we will walk you through everything you need to know about dry ice blasting as a way to strip wood.

What Is Dry Ice?

Manufacturers produce dry ice by turning CO2 to liquid and putting it into a storage tank, where freezing occurs at -109°F and a machine crushes the material into solid ice.

The machines transform dry ice into little pellets or giant blocks. This depends on whether it’s manufactured in a special tool press or if instead, the manufacturer uses a pelletizer.

Dry ice does not melt when it heats up, unlike ordinary ice. Rather, via a process called sublimation, it returns to its original gaseous state. Dry ice has a surface temperature of -109° F, which is substantially lower than the 32° F of ordinary ice.

What Is Dry Ice Blasting?

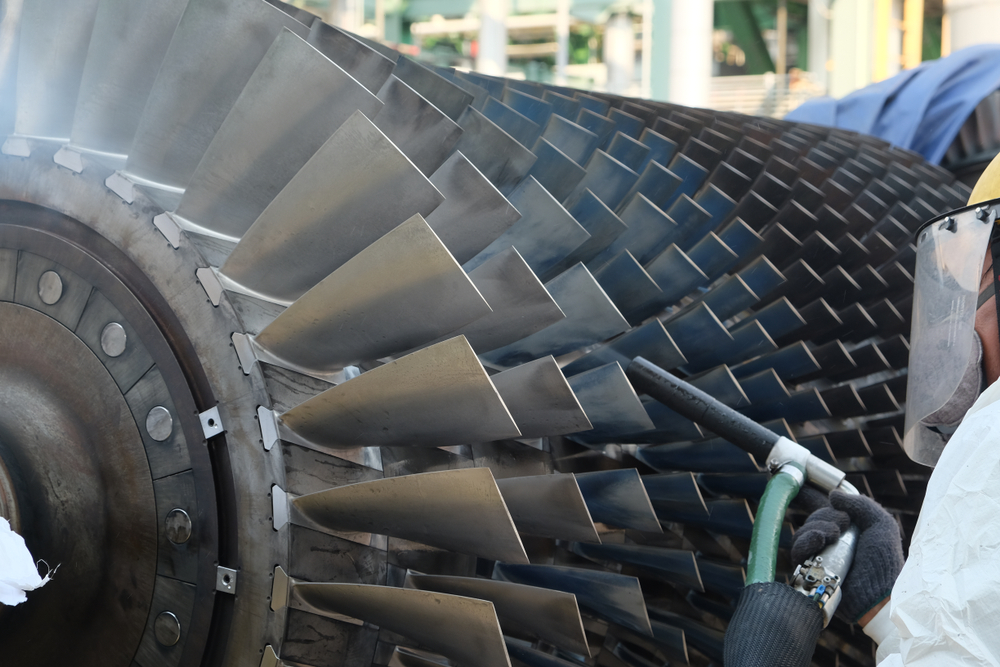

Dry ice blasting uses a high-velocity spray of tiny pellets from dry ice to remove impurities and coatings in the target material, such as surface corrosion, grime, and paint.

It is also known as “dry ice cleaning,” since the solid form of carbon dioxide (CO2), dry ice, sublimates. Solid carbon dioxide dissolves into gas in dry ice sublimation, and there is no intermediary liquid stage.

Typically at 1 atm, this transition happens at a temperature of -78.5° C (-109° F). In order to clean with dry ice, you will need a blast pot, an air compressor, and a variety of attachments, all of which are easily transportable.

It is possible to use abrasive ice blasting, which uses a high-velocity spray of ice particles with an abrasive to clean surfaces and remove contaminants.

Dry ice and abrasive are fed simultaneously into the blaster at a predetermined dose during abrasive ice blasting. Compared to sandblasting, this method generates substantially less dust. Using dry ice polishing and aggressive ice blasting, diamond-shaped particles may be reduced to custom sizes to meet the needs of a variety of different applications.

What Are The Advantages of Ice Blasting With Dry Ice?

Nonabrasive cleaning may be achieved with the use of dry ice pellets, which are CO2 in solid form, as a blasting medium. Upon contact with the edge or material to be cleaned, the dry ice pellets evaporate.

It is possible to clean even sensitive internal house wiring with dry ice cleaning since it is a fully dry method. Surface damage is minimized since the materials are handled with considerable care.

Cleaning with dry ice leaves no residue behind. As long as there is no residue, it’s best to just sweep or vacuum the floor to get rid of it.

Key Advantages of the Material

Silica and other harmful chemicals should not have any use in products for the general public. Dry ice blasting uses no harmful chemicals and is fully non-toxic.

The fact that dry ice comes from CO2 recycled from other industrial processes, while also being relatively safe, is a major differentiating feature.

It doesn’t create emissions since it doesn’t manufacture CO2 or add CO2 to the air. For your safety and for the environment, dry ice blasting is an excellent choice.

You can clean almost any piece of equipment while in use using dry ice blasting. This lowers the amount of time spent disassembling and cleaning.

Using a variety of nozzles and a high-speed cleaning system, you can clean even the most difficult-to-reach areas.

Using dry ice blasting to clean industrial equipment while it is still in situ lowers equipment downtime and the associated expenses.

Production equipment and wooden products may be cleaned more regularly because of the high cleaning speed. As a result, the risk of finished items being below spec and the cost of conducting an additional cycle are reduced.

How Can Dry Ice Blasting Help With Wood Stripping?

Wooden surfaces may suffer damage from conventional cleaning procedures. Secondary waste forms when materials such as sand and other chemicals attempt to alter wood in its original state. It is possible to restore old, weathered wood to its original beauty by using dry ice blasting.

Using a dry ice blaster, you may safely take charring off of wood, eliminate soot, and help eliminate odors from the walls with ease.

When it comes to reviving wood that has been damaged by mold or fire, dry ice blasting is by far the most successful approach because of its low pressure and aggressiveness on rough and smooth surfaces alike.

Dry Ice Blasting Near Me

At the end of the day, dry ice blasting is a great way to remove and strip anything unwanted off of wooden furniture or materials.

Wood surfaces can easily be damaged by alternative cleaning procedures, so dry ice blasting provides a safe option for making a wooden structure good as new. It reduces costs and downtime, especially when used repeatedly in a systematic manner.

If you enjoyed this article about wood stripping, please check out the other articles on our blog! Or contact us today to get a quote if you are interested in dry ice blasting services.