You’re ready to enhance the appearance of your deck by finally replacing that worn-out-looking, hideous paint color with a fresh hue.

Good thinking. Research shows that an attractive deck in your backyard adds an average resale value of more than $7,000.

The problem is, you’re struggling to remove the stubborn paint on your deck. Fortunately, that’s where dry ice blasting comes into play.

Here’s a rundown of everything you need to know about the impact that dry ice blasting can have on paint stripping.

Let’s jump in!

Dry Ice Blasting: How It Works

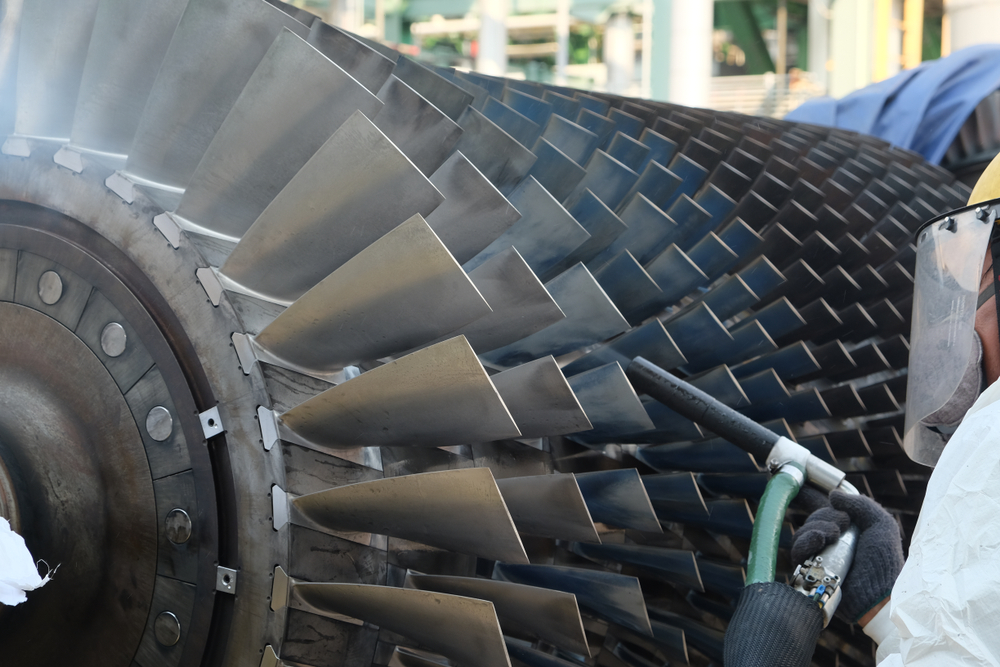

Dry ice blasting involves removing surface contaminants as well as old paint coatings by using pressurized carbon dioxide pellets.

The blasting process causes a powerful thermal shock to occur between two materials that are not alike. This allows for the breaking down and removal of one material (in your case, your paint). And you can do this without causing damage to the other material (your deck surface).

Dry ice blasting offers the benefit of requiring no drying time, as water isn’t used in the cleaning process. In addition, no residual media will be left on the surface you are cleaning.

Dry ice blasting is also a relatively efficient and quick process. Plus, this type of blasting is non-abrasive and non-flammable.

However, the benefits of dry ice blasting don’t stop there. We’ll take a peek at this process’s several other benefits next.

Waste Reduction

One of the top dry ice blasting benefits is that it significantly decreases the dust that traditional paint removal methods generate.

Sandblasting produces large amounts of dust and waste. Unfortunately, this respirable dust can harm the public, the surrounding workforce, and the operator.

Dust is especially a concern if the blasting is taking place where vulnerable individuals, like children or the elderly, will be present. These places may include an elementary school building or a local medical center, for example.

This is why the Occupational Safety and Health Administration encourages the limiting of dust exposure during projects. For instance, exhaustive containment setups are required before people use blasting methods that involve coal slag, crushed glass, and garnet, for example.

Wet blasting — for example, vapor blasting and slurry blasting — can also be problematic.

With this process, an abrasive is combined with water to capture all generated dust molecules. This prevents the dust from becoming airborne and therefore reduces dust levels. However, it still generates waste.

In addition, wet blasting isn’t as productive as dry ice blasting. That’s because water decreases the speed of the abrasive particles used to do the blasting.

Dry ice blasting, on the other hand, offers the benefits of both sandblasting and wet blasting.

The dry ice blasting process produces carbon dioxide gas that suppresses the generated dust. This keeps the dust from going into the air, as carbon dioxide gas weighs more than air does.

The dust reduction that comes with dry ice blasting makes for a healthier environment for breathing. However, it also benefits the operator by increasing their visibility while performing their cleaning job.

Containment and Cleanup Improvement

As we mentioned earlier, containment setup is necessary when you use slurry, vapor, or sandblasting. Unfortunately, the containment process is labor-intensive and time-consuming.

The good news is that with dry ice blasting, you don’t have to worry about containment setups.

In addition, methods like wet blasting produce secondary waste, like water runoff, that has to be disposed of. However, with dry ice blasting, waste cleanup is not necessary.

Finally, let’s say you want to perform your blasting job in a saltwater environment. Chloride and soluble solids accumulate on surfaces in this type of environment. As a result, if you choose wet blasting, you have to complete a pre-wash process before you start the stripping process.

When you choose dry ice blasting, however, no pre-wash steps are needed. That’s because the dry ice can remove chlorides and soluble solids while simultaneously stripping paint from your target surface.

Given the above, using dry ice can save you time. It can also save you money. After all, you won’t have to enlist other people to handle the containment setup, pre-wash, and post-cleaning/waste collection steps.

Also, as we mentioned earlier, dry ice blasting doesn’t require any drying time. So, you can apply fresh paint to your target surface immediately after you’ve finished blasting it.

Environmental and Weather Friendliness

Finally, dry ice blasting is an eco-friendly method of removing paint from a surface.

Not only does dry ice blasting produce less dust, but also it requires less media compared with other blasting methods. As a result, less media enters the surrounding environment.

You’ll also love the fact that dry ice blasting can be performed even when the weather is unfavorable. That means you can get the job done rain or shine.

How We Can Help with Dry Ice Blasting

When done properly, dry ice blasting can be a huge help in the most challenging of paint removal projects. It offers the benefits of reducing waste, minimizing cleanup, and being environmentally friendly.

At Raw Restoration Blasting, we take pride in offering top-tier dry ice blasting services for paint removal in a number of industries.

We can help in the areas of injection molding, residential deck resurfacing, and fire restoration. Our blasting services also help with construction equipment maintenance, marina maintenance, and even preserving historic statutes or landmarks.

Get in touch with us to get a quote for your project today!