Dry ice blasting is an eco-friendly method of cleaning surfaces previously considered difficult to clean, and it handles the cleaning process with virtually no side effects. Dry ice blasting effectively cleans wood, concrete, masonry, metal, marble, and other surfaces, and it does so without leaving any residue other than the substances it removes from the surfaces it cleans. While it sounds too good to be true, dry ice blasting is commonly performed in food processing and industries ranging from semiconductors to oil, automotive, and historical preservation.

So, let’s look at dry ice, the dry ice blasting process, its applications, and why it is eco-friendly across applications.

What Is Dry Ice, and Where Does It Come From?

Carbon dioxide is one of the Earth’s fundamental gases and is dangerous to humans primarily when inhaled in a highly concentrated form. The liquid carbon dioxide that is frozen and compressed is called dry ice, an informal name pointing to the fact that dry ice does not leave a puddle after “melting,” as does frozen water. Instead, dry ice sublimates or transitions from a solid state to a gaseous state without going through a liquid state. As we will describe below, the fact that dry ice sublimates is fundamental to its value in many applications and is critical to its eco-friendliness.

Although carbon dioxide exists in nature, we obtain the carbon dioxide used to make dry ice as a byproduct of various manufacturing processes, so limited energy is used in its creation. We use this byproduct for another productive purpose.

How Does Dry Ice Blasting Work?

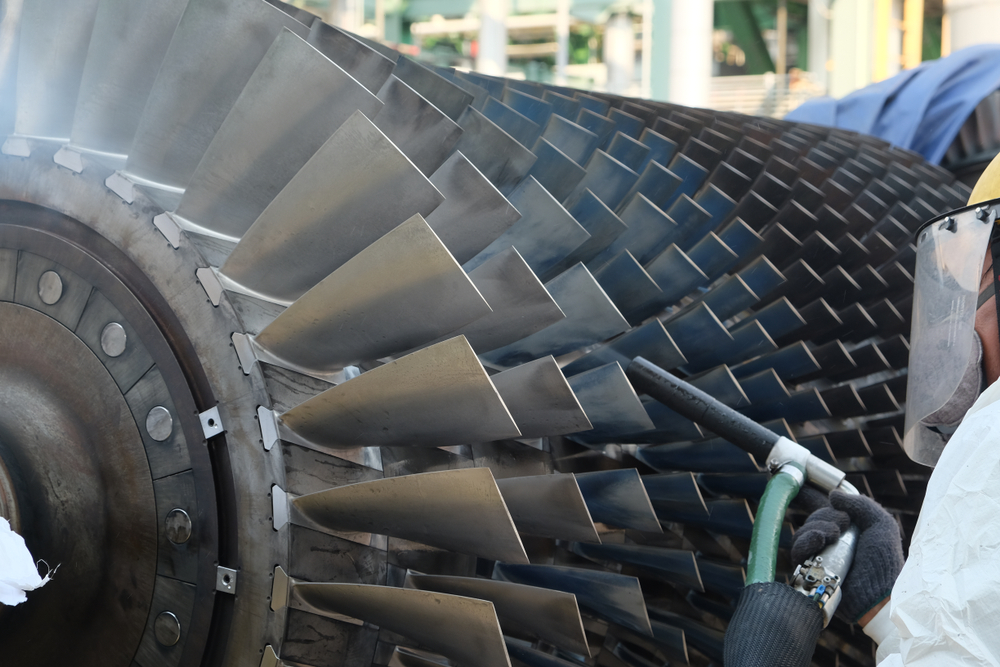

Dry ice blasting is similar to other methods that shoot accelerated sand, walnut shells, or other materials in an air stream to clean a surface. Dry ice pellets are also accelerated in an air steam and shot at a surface. Among the key differences between dry ice and other materials is that dry ice is non-conductive, nonflammable, virtually nonabrasive, and sublimates upon hitting the target surface, leaving behind zero residue.

Dry ice blasting works in part because the low temperature of the dry ice causes thermal shock when it hits a surface, making the adherent (e.g., paint, oil, plastics) brittle so they more easily separate from the surface being cleaned. Unlike sand or other particles that remain behind after blasting, the dry ice sublimates into carbon dioxide and dissipates into the air. The only physical residue left behind is the adherent that was the target of the cleaning, so dry ice blasting minimizes the volume of material requiring cleanup. Eliminating secondary waste is a critical advantage in many applications, mainly when dealing with hazardous waste. In those applications, the sublimated dry ice does not add to the volume of hazardous material that requires disposal.

Dry Ice Blasting Applications

The use of dry ice blasting in the food industry clearly illustrates the eco-friendliness of dry ice blasting. Today, dry ice blasting is approved for use in food and drug processing facilities certified or inspected by the following:

- Environmental Protection Agency

- United States Department of Agriculture

- Food and Drug Administration

- American Institute of Baking

- Global Food Safety Initiative

Dry ice blasting prevents microorganism decontamination by removing salmonella, E. coli, and listeria from production surfaces such as stainless steel and ceramic tile. It also can clean food-grade plastic storage containers.

Previously, food processing plants often needed cleaning agents or other chemicals to sanitize the equipment, followed by rinsing processes to remove the cleaning agents, so equipment cleaning required significant downtime. By using dry ice blasting, companies waste less time and energy cooling and reheating ovens and other energy-intensive equipment.

Focusing on specific applications or functions rather than industries, dry ice blasting offers various opportunities for improvement and eco-friendliness. One notable example is its effectiveness in equipment cleaning without the need for disassembly. This results in significant time and energy savings for heated or cooled machines during production and leads to enhanced energy efficiency as production temperatures rise.

In the past, industries commonly relied on hot water and solvents for cleaning production equipment, storage vessels, and other machinery. These traditional methods necessitated energy consumption for heating water and additional processes for capturing, treating, and disposing of solvents and chemicals. Adopting dry ice blasting brings substantial energy savings throughout the cleaning process.

The nonabrasive nature of dry ice blasting also prolongs the equipment’s lifespan. This longevity reduces the demand for manufacturing, shipping, and installing replacement equipment, subsequently minimizing the need to dispose of the original equipment.

Dry ice is non-conductive, so it is suitable for cleaning equipment with electrical and electronic components and eliminates the need for the caustic chemicals used in the past.

The various applications mentioned above are only the tip of the dry iceberg regarding the positive environmental impact dry ice blasting has had and will have as its use expands in manufacturing and other environments.

Dry Ice Blasting Limitations

Dry ice blasting may not be the best option for cleaning soft surfaces because the pellets travel at high speeds and may damage surfaces such as cloth, softwood, or soft plastic.

It is also inappropriate for enamels and some primers because of its nonabrasive qualities. Dry ice blasting also causes oils and other liquids to splatter, so containment systems are needed for applications that clean those adherents.

Working with Raw Restoration Blasting

If you would like to explore the eco-friendly benefits of dry ice blasting, contact our experts at your earliest convenience. Raw Restoration Blasting is more than just a blasting company. We are a family and veteran-owned business that takes pride in serving the Southeastern Wisconsin community. Our dry ice blasting services have proven to be effective in various industries, from industrial to residential and everything in between.

With our headquarters located in Racine, we are able to serve clients quickly and efficiently throughout the area, including Burlington, WI. If you are curious about how our services can benefit your operation, give us a call at 262-417-6836 for a quote today. Trust our experts for all your restoration needs.