What do you get when you liquefy carbon dioxide (CO2), inject it in a holding tank, freeze it at -109 degrees Fahrenheit? If you guessed dry ice, you’re right on the money. Dry ice mostly comes in pellets or solid blocks, depending on its use.

What makes dry ice so unique is that it doesn’t transform into liquid on cooling. Instead, it converts into gas directly in a process known as sublimation. This property has made dry ice useful for many industrial applications, including dry ice blasting.

Today, we’ll be looking at everything you need to know about dry ice blasting and how it can help you and your business.

A Guide to Dry Ice Blasting: What Is Dry Ice Blasting?

Dry ice blasting is a method of cleaning surfaces that is non-abrasive and leaves no residue. Dry ice blasting involves utilizing CO2 pellets or microparticles to clean surfaces and remove unwanted coatings like rust and paint. It works by blasting the CO2 particles at supersonic speeds, ejecting the dirt and contaminants from surfaces.

Dry ice blasting works better than other blast-cleaning methods like sand-blasting because it leaves no residue after blasting. Immediately the dry ice pellets hit the surface, dry ice heats up and transforms into gas. Apart from not leaving any residue, dry ice is also:

- Non-toxic

- Non-flammable

- Non- abrasive

The Dry Ice Blasting Process

Dry ice blasting starts with the creation of dry ice pellets, which involves compressing liquid CO2. This compression creates dry ice snow after freezing temperatures of -79 degrees Celsius. A hydraulic cylinder compresses this dry ice snow and feeds it into an extruder plate.

Dry ice rods emerge from the extruder plate; the rods get broken down further into pellets. Using a front-end scrambler, you can break down the pellets into even smaller pieces for cleaning intricate machine parts. Dry-blasting entails accelerating the dry ice pellets in a jet stream that sublimates on hitting the surface.

As mentioned earlier, there’s no wastewater, chemicals, and any other residue of the blasting process. However, it’s a good idea to ensure ventilation in enclosed spaces for the CO2 sublimate to escape. In other cases, the CO2 gas will blow away with the wind.

What Can Dry Ice Blasting Clean?

Now that you know what dry ice blasting is, one can’t help but wonder what does dry ice blasting clean? This cleaning method has both household and industrial applications. Here are a few situations where you can use dry ice blasting.

Cleaning Fin Fan Cooler

It’s hard to clean fin fan coolers with a bristle brush, yet they collect lots of dirt and debris. Dry ice blasting is an efficient and effective way to clean fin fans. It clears all dust and debris from the fan and can increase cooling efficiency by 35%.

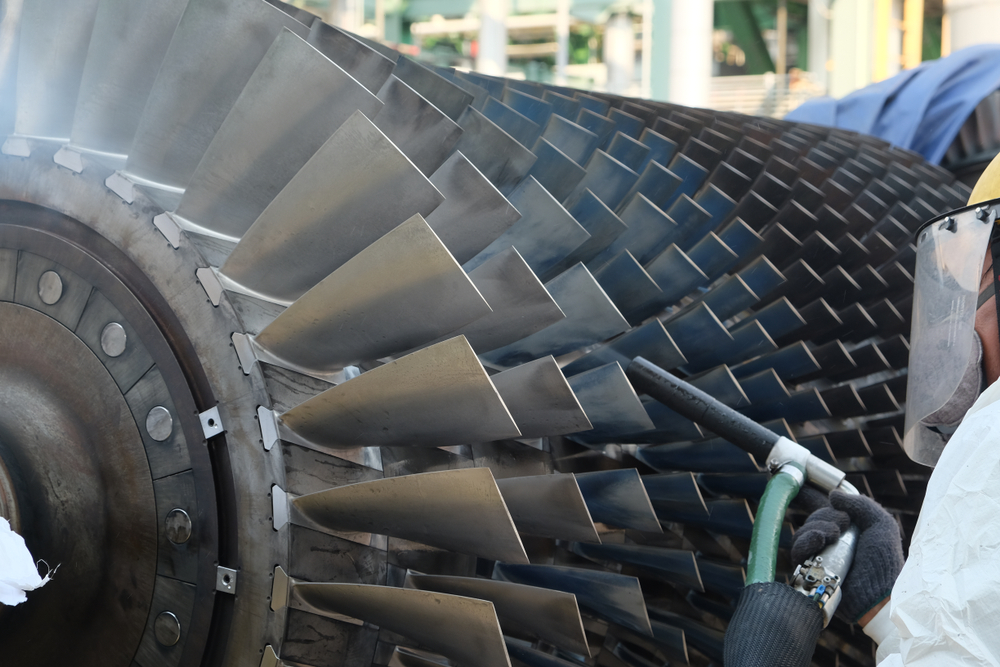

Cleaning Winding sand Turbines in Electric Motors

Keeping electric motors clean could dramatically increase their lifespan. Everyone knows water and electricity don’t mix. This makes it a huge challenge to clean electric motors diligently.

Thankfully, instead of water, you can use a stream of dry ice to clean the turbines. Focus on the windings and turbines since they gather the most dirt. Let dry ice blasting lengthen your motor’s lifespan.

Cleaning Furnaces

Dry ice blasting allows the cleaning of debris off of furnaces. Because it produces no residue, it allows for technicians to work on furnace parts minus the grime. It’s great for removing the debris of furnace walls and improving its efficiency.

Removing Bitumen and Tar From Construction Equipment

Bitumen is heavily used in construction for binding aggregates to create asphalt roads. It’s easy for tar to stick to machine parts and compromise their functionality. Tar can also spill on loading areas and create a hue mesh.

Jetting dry ice at ultra-high velocities can help dislodge tar from these surfaces. Remember, tar is hard to remove because it binds to surfaces. However, the velocity of the pellets is enough to remove the dry ice from these surfaces.

For Cleaning Variable Frequency Drives

Variable frequency drives or VFD are crucial components of AC motors. Carbon build-up over the years may lead to short circuits. Cleaning VFDs requires much diligence so as not to damage crucial parts.

Blasting with dry ice provides an aggressive yet gentle method of cleaning VFDs. Aggressive enough to remove the gunk but gentle enough to avoid damaging delicate parts.

What Are the Benefits of Dry Ice Blasting?

This method of blast cleaning is popular with industries because it offers tons of benefits. Here are a few benefits of dry ice blasting.

Zero Waste disposal

This blast cleaning method produces no waste because the dry ice pellets evaporate into the air. This means you don’t have to spend any time or money on waste disposal. For severe cases, you can simply sweep away the dirt after ejecting it from surfaces.

Great for the Environment

Dry ice is completely non-toxic and non-hazardous. This makes dry ice blasting a better alternative to sand-blasting that uses silica and other harmful chemicals. This makes ice blasting safe blasting for your employees and the environment.

Remember, dry ice is a by-product of various industrial processes. It doesn’t contribute to the greenhouse effect in any way.

Super Effective

This blast-cleaning method is one of the most effective cleaning methods today. If it can eject tar from road surfaces, you can imagine what it can do for your machine. What’s more, the dry ice jet can access intricate parts for a more thorough clean.

Cost-Effective

This is a cost-effective method of cleaning because you don’t have to spend extra on waste disposal. Furthermore, the cleaning will make your machines work more efficiently and save you a bundle.

Give Dry Ice Blasting a Whirl

Adopt dry ice blasting for your surface cleaning today and enjoy all its benefits. Ensure you hire the right ice blasting company to get the best results. Don’t let dust and dirt compromise your productivity.

Request a quote today for professional and expedient dry ice blasting services.