Industrial cleaning is crucial for keeping equipment running efficiently and ensuring a safe work environment. But let’s face it—traditional cleaning methods can be time-consuming, messy, and sometimes even harmful to your equipment or the environment.

That’s where dry ice blasting comes in. This innovative cleaning method is gaining popularity for its ability to deliver exceptional results without the downsides of conventional techniques. At Raw Restoration Blasting, we’re proud to offer dry ice blasting as a fast, effective, and eco-friendly solution for industrial cleaning. Let’s explore the top seven benefits of using this revolutionary method.

Benefits of Using Dry Ice Blasting for Industrial Cleaning

You can expect numerous benefits from using dry ice blasting for your industrial cleaning needs. Here’s a closer look at how this advanced cleaning method can transform your operations:

1. Non-Abrasive Cleaning

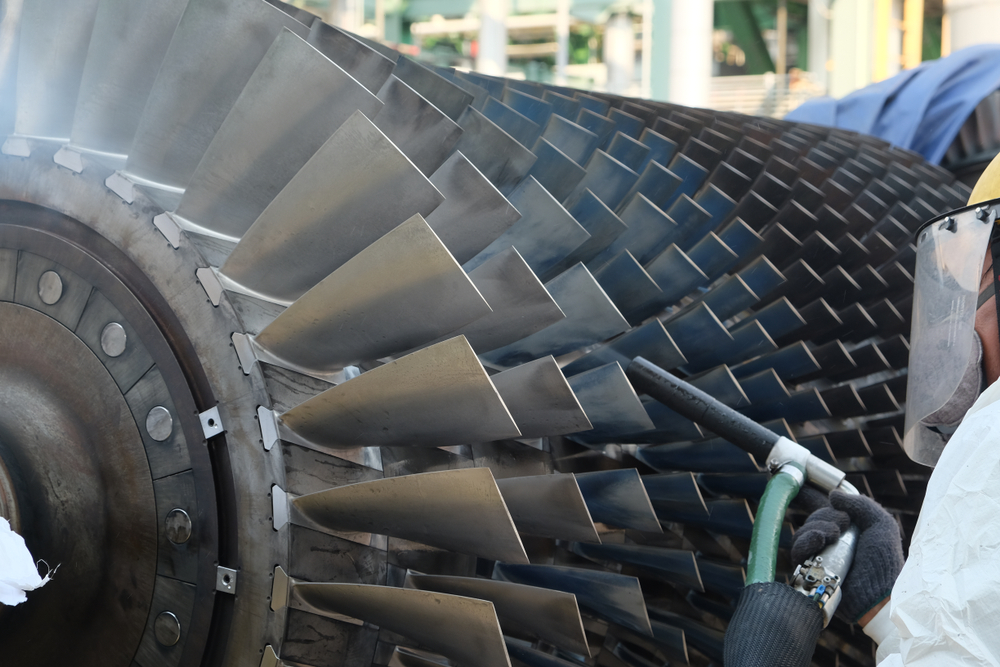

One of the standout advantages of dry ice blasting is its non-abrasive nature. Unlike traditional cleaning methods that rely on harsh scrubbing, abrasive materials, or high-pressure water, dry ice pellets gently lift dirt, grease, and contaminants from surfaces without causing damage. This feature makes it ideal for cleaning delicate machinery, electrical components, and sensitive equipment that could otherwise be harmed by more aggressive methods.

Whether you’re working with precision tools, industrial-grade machinery, or fragile systems, dry ice blasting ensures a thorough clean without compromising the integrity of your assets. At Raw Restoration Blasting, we tailor every cleaning process to meet the specific needs of your equipment, delivering pristine results while protecting your investment.

2. Eco-Friendly Process

For businesses looking to reduce their environmental impact, dry ice blasting is one of the most eco-friendly cleaning methods available today. Unlike traditional processes that use harsh chemicals, solvents, or excessive amounts of water, this innovative method produces no secondary waste. The dry ice pellets used in the process sublimate—meaning they transition directly from solid to gas—leaving no residue or runoff behind.

By eliminating the need for harmful chemicals and significantly reducing water consumption, dry ice blasting minimizes your environmental footprint. It’s a safe, sustainable choice that aligns with modern business values and global sustainability goals. When you choose Raw Restoration Blasting, you’re not only prioritizing efficiency but also committing to a greener, cleaner future.

3. Time Efficiency

In industries where every minute counts, dry ice blasting offers unparalleled time savings. This fast and efficient cleaning method reduces the time required to clean machinery and equipment, helping you avoid costly downtime. Unlike traditional cleaning techniques that may require equipment to be disassembled, this process is performed in place, allowing production to resume quickly.

For example, in manufacturing, automotive, or food processing industries with tight schedules, dry ice blasting ensures that your operations stay on track. At Raw Restoration Blasting, we understand the pressures of industrial timelines, and our team works efficiently to deliver exceptional results without disrupting your workflow. Time is money, and we’re here to help you save both.

4. Enhanced Safety

Safety is a top priority in any industrial setting, and dry ice blasting is one of the safest cleaning methods available. Traditional cleaning methods often involve abrasive tools or harsh chemicals that can harm workers, damage equipment, and pollute the environment. Dry ice blasting eliminates these risks by using a chemical-free process that generates no hazardous fumes or toxic waste.

Additionally, because it’s non-abrasive, there’s no threat of damaging surfaces or creating sharp debris during cleaning. This makes it suitable for even the most sensitive applications. At Raw Restoration Blasting, we take safety seriously and ensure that every cleaning job is carried out to the highest safety standards. Our specialists are trained to deliver effective results while maintaining a hazard-free environment.

5. Versatility Across Applications

One of the reasons dry ice blasting has gained popularity is its incredible versatility. It’s a cleaning solution that adapts to a wide range of industries and applications, making it a go-to option for businesses with diverse needs. Some of its most common applications include:

- Cleaning machinery and equipment in manufacturing plants.

- Removing contaminants like grease, oil, and dirt from electrical components.

- Restoring production lines in food processing or automotive facilities.

No matter your industry, dry ice blasting can be customized to address your specific requirements. Whether you’re looking to clean tough grease from an automotive plant, maintain hygienic conditions in a food processing facility, or keep your sensitive electronics functioning optimally, Raw Restoration Blasting has the expertise to handle it all.

6. Superior Results

When it comes to industrial cleaning, results are everything. Dry ice blasting delivers a deep, thorough clean that is hard to achieve with other methods. By using compressed air and dry ice pellets, this technique effectively removes stubborn contaminants like grease, grime, oil, and dirt—even in hard-to-reach areas.

The benefits of these superior results extend beyond appearance. A cleaner environment improves operational efficiency, enhances workplace safety, and extends the lifespan of your equipment. At Raw Restoration Blasting, we take pride in not only meeting but exceeding your expectations, providing results that truly make a difference for your business.

7. Cost-Effectiveness

While the upfront cost of dry ice blasting might seem higher than traditional cleaning methods, it offers significant long-term savings that make it a smart investment. Here’s how it helps reduce costs:

- Lower Labor Costs: It’s a faster process, meaning less time and fewer resources are spent on cleaning.

- Minimized Downtime: Your operations resume quickly, maximizing productivity and reducing downtime.

- Extended Equipment Lifespan: By gently cleaning without causing wear and tear, dry ice blasting helps prevent damage and reduces the need for costly repairs.

For businesses of all sizes, these advantages add up to substantial savings over time. At Raw Restoration Blasting, we’re committed to providing cost-effective solutions that enhance your bottom line while delivering exceptional results.

From its non-abrasive and eco-friendly nature to its time-saving efficiency and superior results, dry ice blasting is a game-changer in industrial cleaning. Whether you’re looking to improve safety, reduce costs, or achieve a deeper clean, this innovative method is designed to meet the needs of modern industries. Let Raw Restoration Blasting show you the difference dry ice blasting can make for your business. Contact us today to learn more!

Contact Our Team Today

Ready to experience the benefits of dry ice blasting for your industrial cleaning needs? At Raw Restoration Blasting, we specialize in providing fast, efficient, and eco-friendly solutions that keep your operations running smoothly.

Give us a call at (262) 417-6836 to schedule a free estimate and find out how dry ice blasting can make a difference for your business. Let our team help you achieve a cleaner, safer, and more efficient work environment today!