Industrial equipment needs regular maintenance to keep operations running smoothly. But traditional cleaning methods can be messy, damaging, or even hazardous to your equipment. That’s why more companies across Burlington, WI are turning to dry ice blasting, a safe, fast, and environmentally friendly way to clean machinery without causing harm.

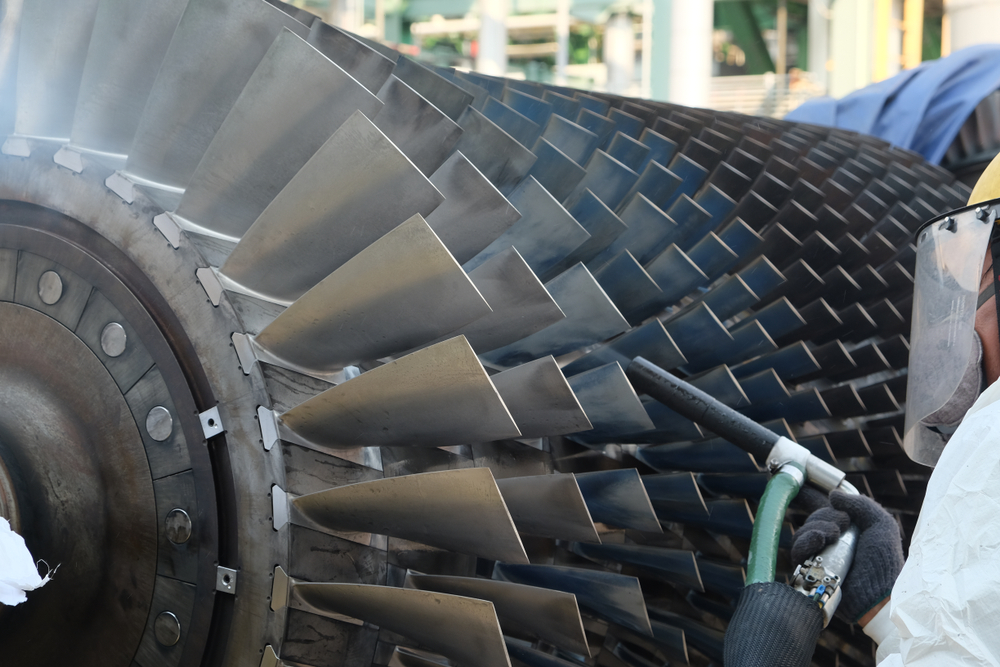

Dry ice blasting is a non-abrasive cleaning process that uses dry ice pellets shot at high speed with compressed air. As the pellets hit the surface, they lift off dirt, grease, and contaminants without damaging the equipment. The dry ice instantly turns into gas, leaving no residue behind.

At Raw Restoration Blasting, we specialize in dry ice blasting for industrial clients who need fast, effective, and safe cleaning. Here’s why this method is considered one of the best in the industry.

What Makes Dry Ice Blasting Unique?

Unlike sandblasting, power washing, or chemical scrubbing, dry ice blasting is completely dry and non-toxic. There’s no water involved, no abrasive grit, and no harsh chemicals. This makes it the ideal method for cleaning sensitive or high-value equipment that can’t be exposed to moisture or harsh materials.

The dry ice pellets sublimate upon impact, which means they turn from solid to gas without leaving any waste behind. You’re left with only the removed contaminants—no water puddles, no sludge, no grit to clean up.

Top Benefits of Dry Ice Blasting

1. It’s Safe for Equipment

Dry ice blasting doesn’t scratch, warp, or erode surfaces. It can be used on metal, plastic, rubber, and even electrical components. It’s perfect for cleaning motors, conveyors, circuit boards, and complex machinery with no risk of damage.

2. No Moisture, No Drying Time

Because it’s completely dry, there’s no downtime waiting for equipment to dry. This is especially important in industries where rust or electrical damage can occur with water-based methods.

3. No Secondary Waste

Since the dry ice disappears into gas, there’s no leftover blasting media to clean up. This drastically reduces cleanup time and keeps your workspace cleaner.

4. Eco-Friendly and Chemical-Free

Dry ice blasting uses carbon dioxide that is recycled from other processes, so it doesn’t add new emissions to the environment. There are no toxic chemicals involved, making it safe for workers and eco-conscious businesses.

5. Reduces Downtime

Cleaning can often be done without disassembling equipment, which saves time and avoids production delays. It’s ideal for facilities that need fast turnaround during maintenance periods.

Where Can Dry Ice Blasting Be Used?

This method is incredibly versatile and used across many industries, including:

- Manufacturing plants: Clean conveyor belts, molds, presses, and production lines

- Food processing: Sanitize surfaces without moisture or chemicals

- Electronics: Clean circuit boards, panels, and sensitive systems safely

- Automotive and aerospace: Remove grease, sealant, and paint from parts

- Historical restoration: Gently clean old structures or machinery without damage

At Raw Restoration Blasting, we’ve worked with clients across all these sectors, delivering results that go beyond expectations with dry ice blasting.

Why Choose Dry Ice Blasting Over Other Methods?

Traditional cleaning methods can often do more harm than good. Sandblasting is abrasive and can damage delicate surfaces. Power washing introduces water, which can lead to rust or electrical issues. Chemical cleaning can leave harmful residues and pose safety risks.

Dry ice blasting avoids all of these problems. It cleans thoroughly without adding moisture, abrasives, or toxins. It’s a safer, smarter choice for modern industrial cleaning.

Trust Raw Restoration Blasting for Your Next Project

Based in Burlington, WI, Raw Restoration Blasting is proud to be a trusted name in industrial cleaning. Our experienced team knows how to clean your equipment safely and efficiently using dry ice blasting. We work with manufacturers, facility managers, and maintenance teams to keep equipment in top shape without disrupting operations.

Our technicians are fully trained, and we bring mobile dry ice blasting services directly to your facility. Whether you need routine cleaning or emergency service, we tailor each project to fit your schedule and needs.

Ready to Make the Switch?

If your current cleaning process is time-consuming, damaging, or messy, it’s time to upgrade. Dry ice blasting offers a faster, cleaner, and safer alternative that protects your equipment and your bottom line.

Contact Us Today

Let Raw Restoration Blasting show you the difference that dry ice blasting can make. We serve Burlington and the surrounding Wisconsin communities with fast, reliable service and expert results. Contact us today or call (262) 417-6836 to request your free quote and schedule a consultation.