Scraping, sanding, and harsh chemicals. Removing old paint is often the worst part of a restoration project. It’s messy, time-consuming, and can damage the surface underneath. What if there was a better, cleaner way? That’s where dry ice blasting comes in. This advanced technology is transforming paint removal, offering a method that is not just effective but often far superior to traditional techniques.

What Exactly Is Dry Ice Blasting?

Dry ice blasting is a powerful cleaning process that uses recycled carbon dioxide (CO2) in the form of solid pellets. These pellets, about the size of rice grains, are accelerated in a high-velocity airstream and directed at the painted surface. When the pellets hit the paint, three things happen almost instantly. First, the kinetic energy of the pellet hitting the surface starts to break up the brittle paint. Second, the extreme cold (-109°F) causes “thermal shock,” which cracks the coating. Finally, upon impact, the dry ice pellet instantly turns from a solid to a gas—a process called sublimation. This rapid expansion of gas, about 800 times the pellet’s size, acts like a micro-explosion that lifts the paint right off the substrate.

The Effectiveness: Paint vs. Dry Ice

When it comes to paint removal, the simple answer is yes, dry ice blasting is exceptionally effective. It excels at breaking the bond between the paint coating and the underlying material. Unlike sandblasting, which grinds the paint and the substrate away, this method shatters and lifts the paint layer. This makes it ideal for removing multiple layers, tough industrial coatings, and even delicate jobs where preserving the original surface detail is critical. The force is adjustable, allowing a skilled technician to remove just the topcoat or strip it all down to the bare material, providing a level of control that other methods lack.

Why Choose This Method Over Others?

The effectiveness is clear, but the benefits are what truly set this process apart. Traditional methods come with major trade-offs that dry ice blasting simply eliminates.

It’s Completely Non-Abrasive

This is arguably the biggest advantage. Sand, soda, or glass beads are abrasives; they wear down the target surface by friction. Dry ice is not. Because the CO2 pellets sublimate on impact, nothing is left to grind against the substrate. This means you can strip paint from wood without raising the grain, from metal without causing pitting or warping, and from fiberglass or carbon fiber without damaging the delicate composite structure. It preserves the original integrity of the asset, which is crucial for classic cars, historical buildings, and complex machinery.

It’s a Clean, Dry, and Eco-Friendly Process

Think about the cleanup from sandblasting—piles of contaminated sand. Or chemical stripping—toxic sludge that needs special disposal. Dry ice blasting eliminates this. The C02 pellets simply vanish into the air, returning to the atmosphere as a gas. The only thing left to sweep up is the paint chips that were removed. There’s no secondary waste, no water to cause rust or mold, and no harsh solvents. It’s an EPA-approved method that’s safe for the environment and for employees.

It’s Incredibly Fast and Efficient

This method saves a significant amount of time. There is minimal setup and even less cleanup. Often, equipment or parts can be cleaned “in-place” without the need for time-consuming disassembly. The process itself is fast, stripping coatings in a fraction of the time it would take to sand or scrape by hand. For industrial settings, this means less downtime for machinery. For restoration projects, it means moving on to the refinishing stage much sooner.

What Can It Remove Paint From?

The versatility of dry ice blasting makes it a powerful solution across many industries. It is highly effective for:

- Automotive Restoration: Safely stripping paint, primer, and undercoating from car frames and bodies without warping metal.

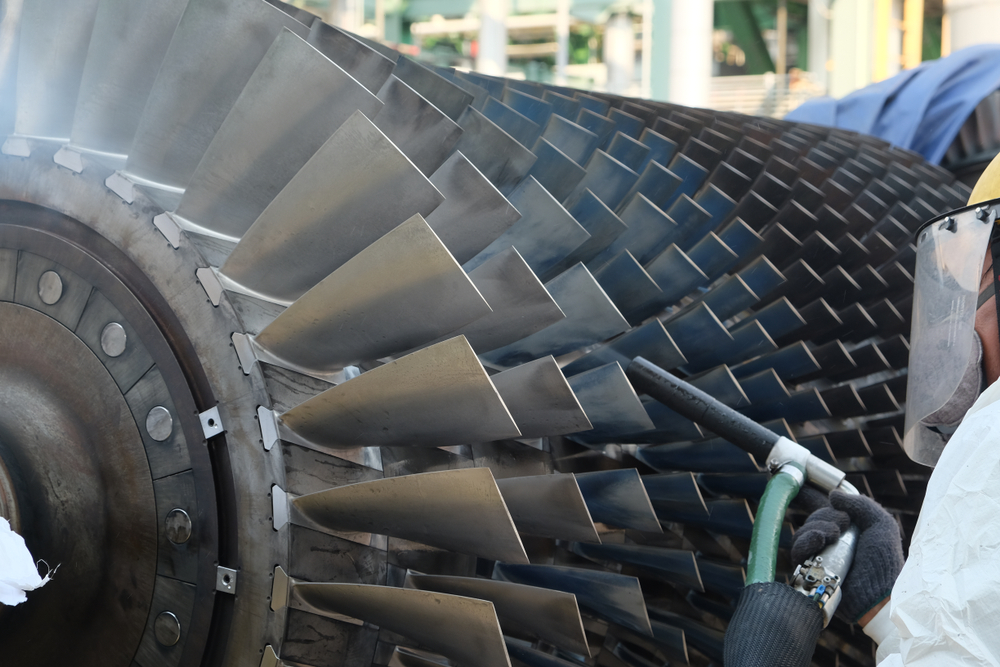

- Industrial Maintenance: Cleaning paint, grease, and grime from conveyors, presses, molds, and other manufacturing equipment.

- Historical Restoration: Removing lead-based paint or graffiti from delicate brick, stone, or woodwork without damaging the historical substrate.

- Marine Applications: Stripping anti-fouling paint from boat hulls without harming the gel coat.

- General Property: Removing unwanted paint from concrete floors, building exteriors, and structural steel.

Is It the Right Choice for Your Project?

While highly effective, it’s important to be transparent: no single method is perfect for 100% of jobs. The effectiveness can depend on the type of paint and the substrate. For example, some soft, flexible elastomeric coatings might absorb the impact rather than shatter, making them more difficult to remove. This is why a professional assessment is so important. A true expert will analyze the coating, the substrate, and your goals to determine if dry ice blasting is the most efficient and safest path forward. It’s about using the right tool for the right application.

Contact Raw Restoration Blasting for Your Dry Ice Blasting Needs

So, how effective is dry ice blasting for paint removal? It is a premier solution offering unparalleled benefits in speed, cleanliness, and surface safety. By eliminating abrasion and secondary waste, it sets a new standard for restoration and industrial cleaning. It’s not just about removing paint; it’s about preserving the value of what’s underneath.

If you’re tired of messy and damaging methods, it’s time to see the future of surface preparation. Ready to tackle your project with dry ice blasting? Contact us or see our services page to learn more.