When it comes to heavy-duty surface cleaning or restoration, two methods often come to mind: dry ice blasting and sandblasting. Both are powerful cleaning techniques used in industrial, automotive, commercial, and even residential projects. While they share a few similarities, the differences between them are important and could affect your project’s outcome, surface condition, and environmental safety.

At Raw Restoration Blasting in Burlington, WI, we specialize in dry ice blasting, and we’re here to help you understand why it may be the better choice for your needs. Let’s break down the key differences between these two blasting methods and how to decide which one is right for you.

What Is Sandblasting?

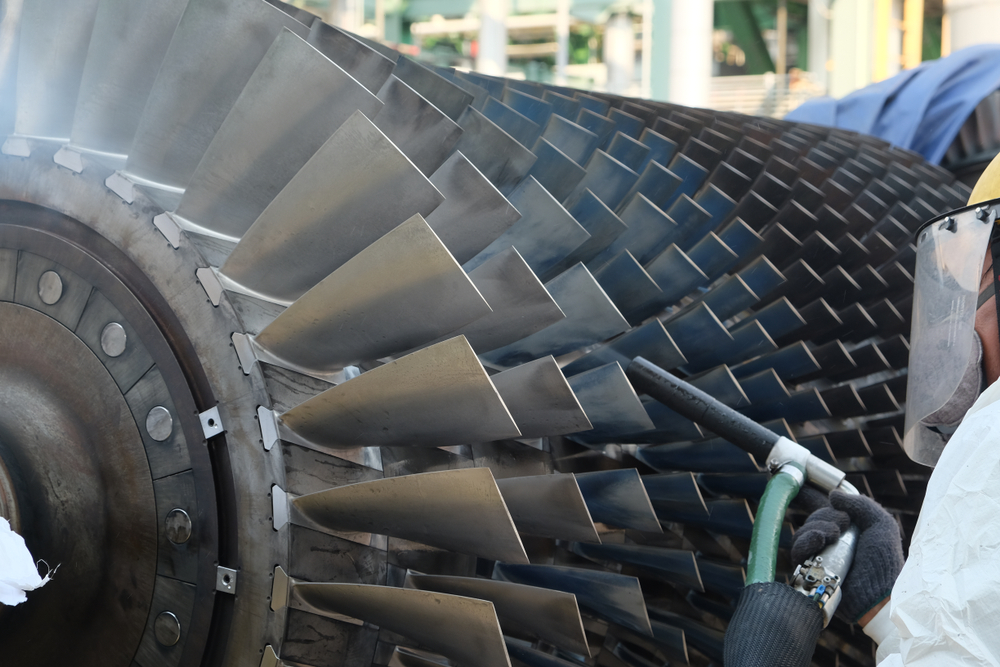

Sandblasting, also called abrasive blasting, uses high-pressure air to shoot abrasive materials like sand, glass beads, or aluminum oxide at a surface. The goal is to strip paint, rust, or grime and leave the surface clean or ready for refinishing.

It’s effective, but not without drawbacks. Sandblasting can damage delicate surfaces and create a significant amount of dust and waste. That means more cleanup, protective gear, and disposal concerns. It’s also not ideal for sensitive equipment, electrical components, or surfaces that can’t withstand abrasion.

What Is Dry Ice Blasting?

Dry ice blasting is a non-abrasive, eco-friendly cleaning method that uses compressed air to blast small pellets of solid dry ice, the solid form of carbon dioxide, at dirty or contaminated surfaces. The dry ice sublimates on contact, turning directly from solid to gas, which means no secondary waste.

The cleaning power comes from three things:

- Thermal shock (rapid freezing weakens the bond between dirt and surface)

- Kinetic energy (the impact of the pellets)

- Gas expansion (the rapid expansion of CO₂ gas lifts contaminants away)

Unlike sandblasting, dry ice blasting doesn’t scratch or etch the surface, making it perfect for sensitive equipment, food processing areas, electrical panels, historical restoration, and more.

Key Differences Between Dry Ice Blasting and Sandblasting

Let’s dive into how these two methods really stack up.

1. Surface Impact

- Sandblasting: Very abrasive; it can remove rust and paint but may also damage softer surfaces.

- Dry Ice Blasting: Non-abrasive; safe for delicate machinery, wood, plastics, and electronics.

2. Cleanup

- Sandblasting: Leaves behind a lot of sand or other abrasive material. Extra time and cost are needed for cleanup and disposal.

- Dry Ice Blasting: Leaves no residue. The dry ice evaporates on contact, meaning there’s virtually zero cleanup.

3. Environmental Safety

- Sandblasting: Creates dust and particulate matter that may require protective gear and controlled environments.

Dry Ice Blasting: Environmentally friendly. No water, chemicals, or harmful byproducts. Ideal for indoor use.

4. Applications

- Sandblasting: Good for removing thick coatings, corrosion, or paint on metal and concrete.

- Dry Ice Blasting: Great for delicate restoration, mold remediation, automotive detailing, and industrial equipment.

5. Cost and Time Efficiency

- While both methods have their place, dry ice blasting often saves time and money by reducing cleanup and minimizing surface damage that could require repair or repainting.

Why Choose Dry Ice Blasting from Raw Restoration Blasting?

At Raw Restoration Blasting, we specialize in dry ice blasting because it’s safer, cleaner, and more versatile for many of our clients in Burlington, WI, and the surrounding area.

Whether you’re cleaning grease off factory equipment, restoring old wood beams, or removing soot after a fire, dry ice blasting gets the job done with minimal disruption.

Common Industries That Use Dry Ice Blasting:

- Manufacturing and production facilities

- Automotive shops and restoration experts

- Food processing plants

- Historical buildings and antiques

- Fire and smoke damage cleanup

We’ve worked on everything from commercial kitchens to classic cars, and our clients love that there’s no mess left behind and no risk to sensitive components.

Is Dry Ice Blasting Always the Best Choice?

In most cases, yes. However, it depends on your project. If you’re stripping several layers of paint off a thick steel beam, sandblasting might be more effective. But if you’re trying to clean intricate machinery, remove mold, or restore something fragile, dry ice blasting is hands-down the better choice.

Our team is happy to assess your project and recommend the right solution. At Raw Restoration Blasting, we don’t just blast. We bring experience, safety, and care to every job.

Ready to Experience the Difference?

Dry ice blasting offers a powerful, non-damaging way to clean surfaces without the mess and risk of traditional sandblasting. It’s efficient, safe, and ideal for both industrial and delicate applications.

Let Raw Restoration Blasting show you how this modern method can save time, reduce waste, and deliver cleaner results.

To get started, get a quote today or give Raw Restoration Blasting a call at (262) 417-6836. We’re here to help restore, clean, and refresh your space with the power of dry ice.