When it comes to powerful, efficient, and eco-friendly cleaning solutions, dry ice blasting is quickly becoming a go-to option across multiple industries. It’s not just because it’s faster than traditional methods, but also because it’s safer for surfaces, non-toxic, and doesn’t leave behind secondary waste. At Raw Restoration Blasting, we’ve seen firsthand how this technology can change the way companies approach deep cleaning and maintenance. But what industries are using this method the most and why? Let’s break it down in simple terms.

Industries That Use Dry Ice Blasting Services

1. Automotive Industry

In the world of car manufacturing and repair, keeping equipment and parts clean is super important. Dry ice blasting works great because it removes grease, oil, and paint without damaging delicate parts. It’s also perfect for restoring classic cars. Mechanics and body shops love it because it doesn’t require drying time and gets into hard-to-reach areas. Our team has helped many auto shops clean engines, molds, and frames using dry ice blasting, saving them both time and labor.

2. Food and Beverage Processing

This might surprise you, but food factories use dry ice blasting a lot! Because it’s a dry and chemical-free method, it’s safe to use around food equipment. It removes bacteria, grease, and even burnt-on residue without shutting down production lines. Our team regularly helps food processing plants maintain a clean and safe environment with this technique. It keeps their machines clean while avoiding contamination, which is super important in this industry.

3. Manufacturing and Industrial Facilities

Large factories and industrial plants are full of machinery that gets dirty fast. Instead of taking everything apart or using water that can cause rust, companies use dry ice blasting. It’s fast, effective, and doesn’t wear down the equipment. Our experts at Raw Restoration Blasting have helped clean everything from production lines to conveyor belts, keeping machines running smoothly. Dry ice blasting reduces downtime, which means more productivity and fewer delays.

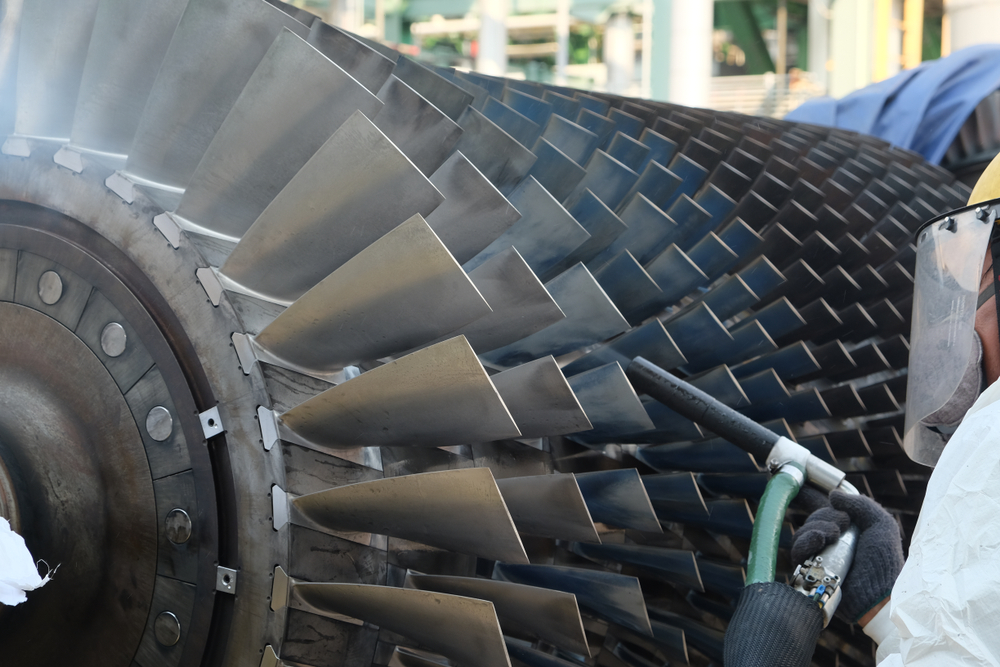

4. Power Plants and Utilities

Power plants deal with heavy buildup on turbines, pipes, and other equipment. Traditional cleaning methods can be messy and even dangerous. That’s why dry ice blasting is a safer choice. It doesn’t involve chemicals or moisture, so it protects electrical components. We’ve helped utility companies maintain their systems with ease, and the best part is they don’t need to shut down operations for cleaning. That saves a lot of time and money.

5. Historical Restoration and Museums

Old buildings, statues, and even museum pieces need to be cleaned with extreme care. Harsh scrubbing or chemicals can ruin them. That’s where dry ice blasting really shines. It gently removes dirt, mold, smoke damage, and graffiti without hurting the original surface. Our team takes pride in preserving history by using this modern method. Museums and restoration groups trust us to clean fragile items safely.

6. Printing Industry

Ink can be tough to clean off machines, and using water or chemicals can cause damage. Printers now use dry ice blasting to remove ink buildup and paper dust from their equipment. It’s clean, quick, and keeps their machines running without interruption. We’ve partnered with printing companies who are amazed at how much longer their equipment lasts thanks to routine dry ice blasting.

7. Marine and Shipping

Boats and ships collect all sorts of grime from saltwater, barnacles, and oil. Traditional cleaning often takes days. Dry ice blasting helps clean boat hulls, engines, and ship parts without needing to haul out all the equipment. We’ve worked with marine companies to keep their fleets clean and corrosion-free. It’s perfect for tight spaces and delicate surfaces.

8. Aerospace and Aviation

Precision is everything in the aerospace industry. Aircraft parts must be spotless, but also undamaged. That’s why dry ice blasting is ideal. It removes carbon, oil, and other residues without harming electronics or delicate surfaces. Our team has cleaned aircraft parts and maintenance areas to help keep planes safe and ready for flight.

9. Electronics and Technology

In the tech world, circuit boards and computer components can’t get wet. Dry ice blasting is dry and non-abrasive, so it’s safe to use on sensitive electronics. We’ve helped companies clean dust and dirt from large server rooms and electronics manufacturing lines using this method. It’s an efficient way to keep devices in top shape without risk.

10. Residential and Commercial Restoration

From house fires to mold infestations, restoration companies often call on dry ice blasting to handle tough cleanup jobs. It removes smoke damage, soot, mold, and even old paint without damaging wood, brick, or stone. Homeowners and business owners are always amazed at how effective and gentle it is. At Raw Restoration Blasting, we use dry ice blasting to help families and businesses recover faster from disasters.

Contact Us Today

Dry ice blasting is not only powerful, but it’s also environmentally friendly. It doesn’t leave behind dirty water or toxic waste. It saves companies time, keeps workers safe, and protects valuable equipment. That’s why more and more industries are choosing this method, and why we’re proud to offer it as a core service.

Whether you’re dealing with machinery buildup, fire damage, or delicate surfaces, we’ve got the tools and experience to get it done right. Click here to get a quote today and let us show you the Raw Restoration Blasting difference. Call our team at Raw Restoration Blasting at (262) 417-6836 for expert service you can trust.